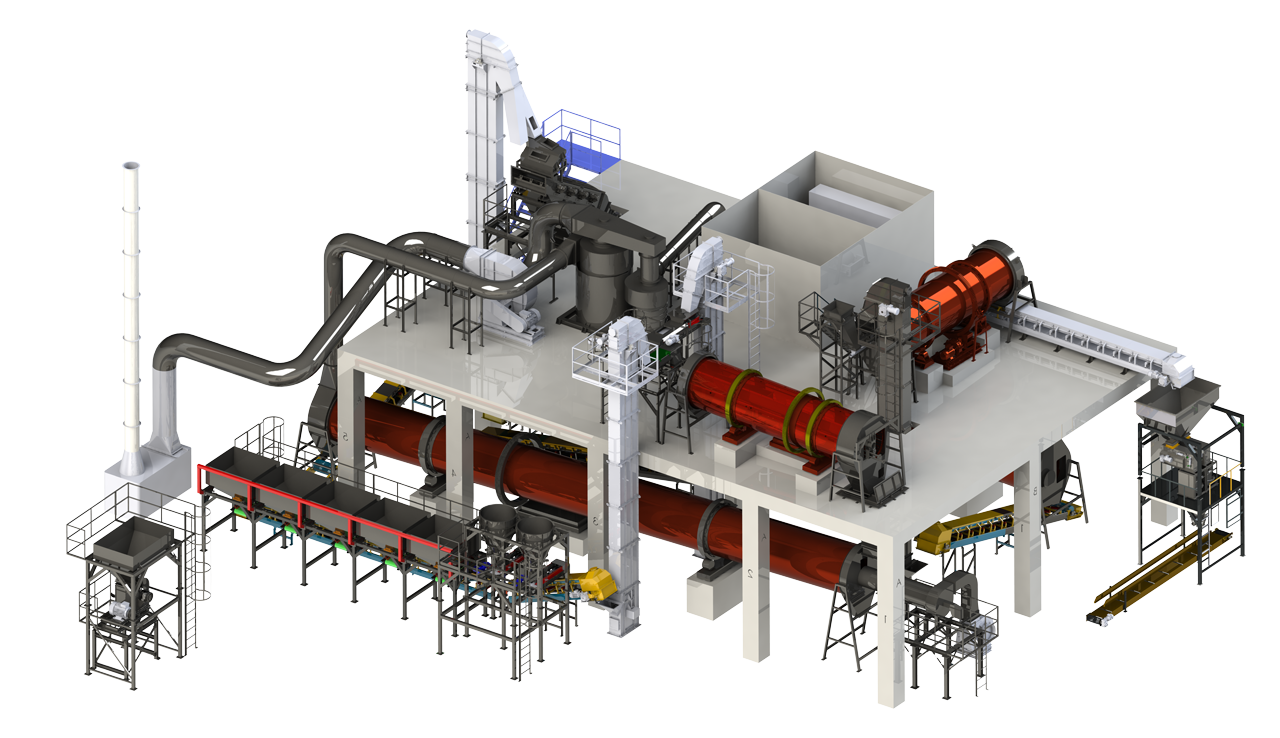

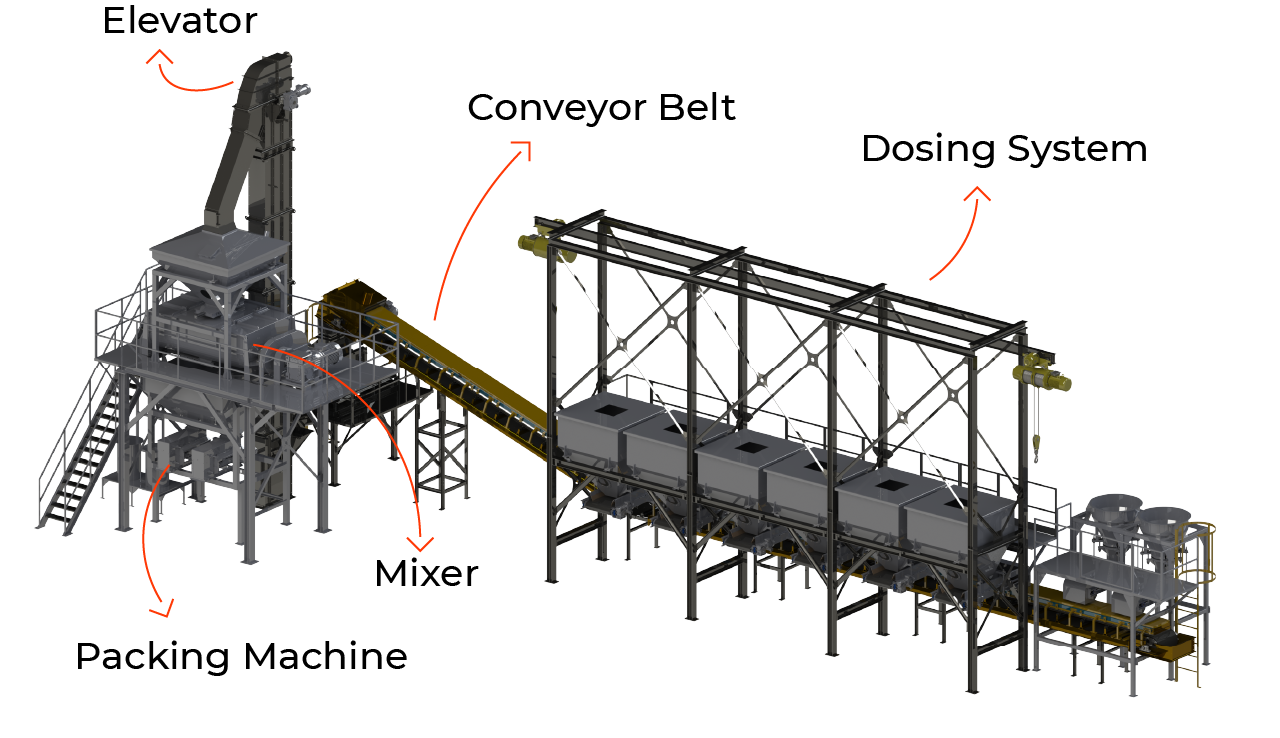

Fertilizer Dosing System Manufacturer

High-Precision Feeding

Robust Corrosion Allowance

Efficient material flow

General Knowledge about Dosing Systems

In any continuous-flow process—whether you are formulating fertilizers, blending animal feed, compounding detergents, or making battery cathode mixes—the dosing system is the gatekeeper of recipe accuracy. Its core job is to meter solid or liquid ingredients at precisely the right rate so the downstream equipment sees a perfectly balanced “diet.” Most plants choose between two fundamental approaches:

Volumetric dosing

Relies on a fixed-speed screw, belt, or rotary valve whose displacement per revolution is known. It is simple and inexpensive but assumes bulk density stays constant; if your prilled urea suddenly absorbs moisture, the mass flow will drift even though the volumetric flow is identical.

Gravimetric (weight-based) dosing

Measures the actual mass in real time—either by weighing the hopper and subtracting (“loss-in-weight”) or by placing a belt conveyor on load cells (“weigh-belt”). The controller continuously adjusts feeder speed to keep the mass flow on setpoint, compensating for density, temperature, or particle-size changes. Because it references true weight, gravimetric dosing routinely achieves accuracies of ±0.25 % to ±0.5 %, meeting OIML R61 Class 0.5 requirements for trade-legal pack-off lines.

Regardless of the principle, a modern dosing skid usually combines:

-

Hoppers and feeders sized for surge volume and flow characteristics (twin screws for cohesive powders, belts for friable granules)—all fundamental sub-assemblies of a fertilizer dosing system.

-

Sensors—load cells for weight, encoders for speed, sometimes microwave or near-infra-red probes for moisture compensation.

-

Controls—a PID loop running in a PLC or embedded controller, networked over EtherNet/IP, PROFINET, or Modbus to the plant SCADA.

-

Hygienic and safety features like 304/316L stainless steel contact surfaces, tool-free clean-out, explosion-relief panels, and aspiration ports to keep respirable dust below regulatory thresholds.

-

Compliance tools such as auto-calibration routines, audit-ready data historians, and recipe management with electronic signatures for GMP or ISO 9001 traceability.

When specified and maintained correctly, a dosing system does far more than feed product; it safeguards product quality, reduces rework, and provides the data backbone for continuous improvement and regulatory audits.

Emerging Trends, Design Pitfalls, and ROI Metrics

The newest generation of fertilizer dosing systems is being shaped by three converging trends.

First, digitalization:

Ethernet-based load cells, vibration-immune piezo sensors, and high-speed edge controllers now stream time-stamped mass-flow data directly to plant historians or cloud analytics platforms. Operators can spot drift patterns days before they trigger an off-spec batch, while machine-learning models fine-tune PID gains on the fly to squeeze another 0.1 % out of accuracy.

Second, modular hygienic design:

Sliding rail undercarriages, inflatable seals, and CIP (Clean-in-Place) spray balls let plants switchover from an NPK blend to an organic compost premix in under an hour without manual scraping—critical for multiproduct toll facilities.

Third, regulatory pressure:

In fertilizer and feed, ATEX/IECEx directives now require documented explosion-risk assessments; dosing hoppers larger than 1 m³ may need relief vents, grounding studs, and antistatic linings. Meanwhile, EU dust-emission limits are tightening to 3 mg m⁻³, pushing integrators toward enclosed weigh-belt systems with integrated HEPA filtration especially in any fertilizer dosing system built for EU markets..

Several design missteps still haunt retrofit projects. Undersizing hopper skirts chokes cohesive powders, mounting load cells off-axis induces hysteresis, and ignoring thermal expansion in screw shafts warps pitch—each costing far more in downtime than the upfront saving. A disciplined HAZOP review and a bulk-solids flow test can avert most of these headaches.

Finally, a well-specified gravimetric skid pays for itself quickly. Plants that replace manual bag tipping with automated dosing typically report 1–3 % formulation yield gains, 50–70 % labor savings, and eight-to-twelve-month payback periods—especially when real-time mass data feeds an ERP system that optimizes procurement and inventory.

Ceylan Liman Hizmetleri Makine İmalat San.ve Tic.Ltd.Şti

|

Çilek Mah. 63142 Sokak No:23 / A (Tırmıl Sanayi Sitesi Karşısı ) Akdeniz/Mersin |

|

E-Mail

|

|

Phone

|

|

Phone

|

|