Deliver advanced-level fertilizer production plants.

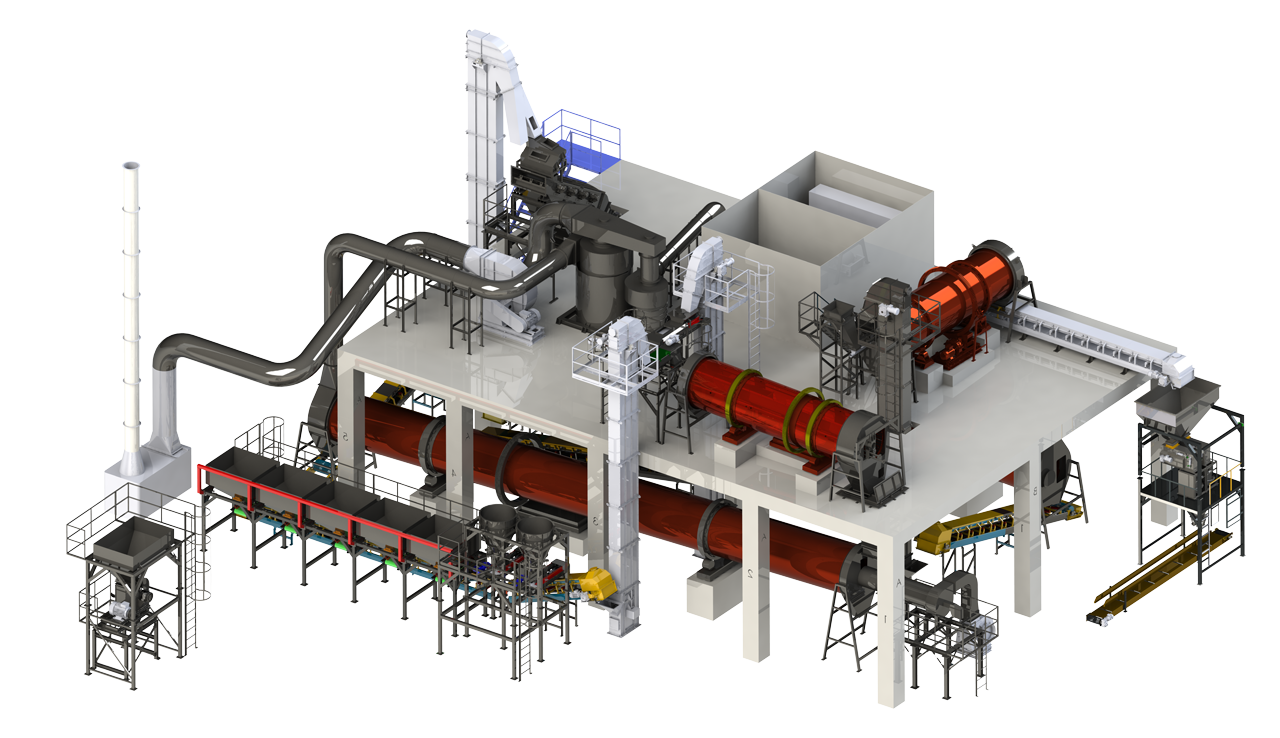

Drying

Screening & Sifting

Crushing

Cooling

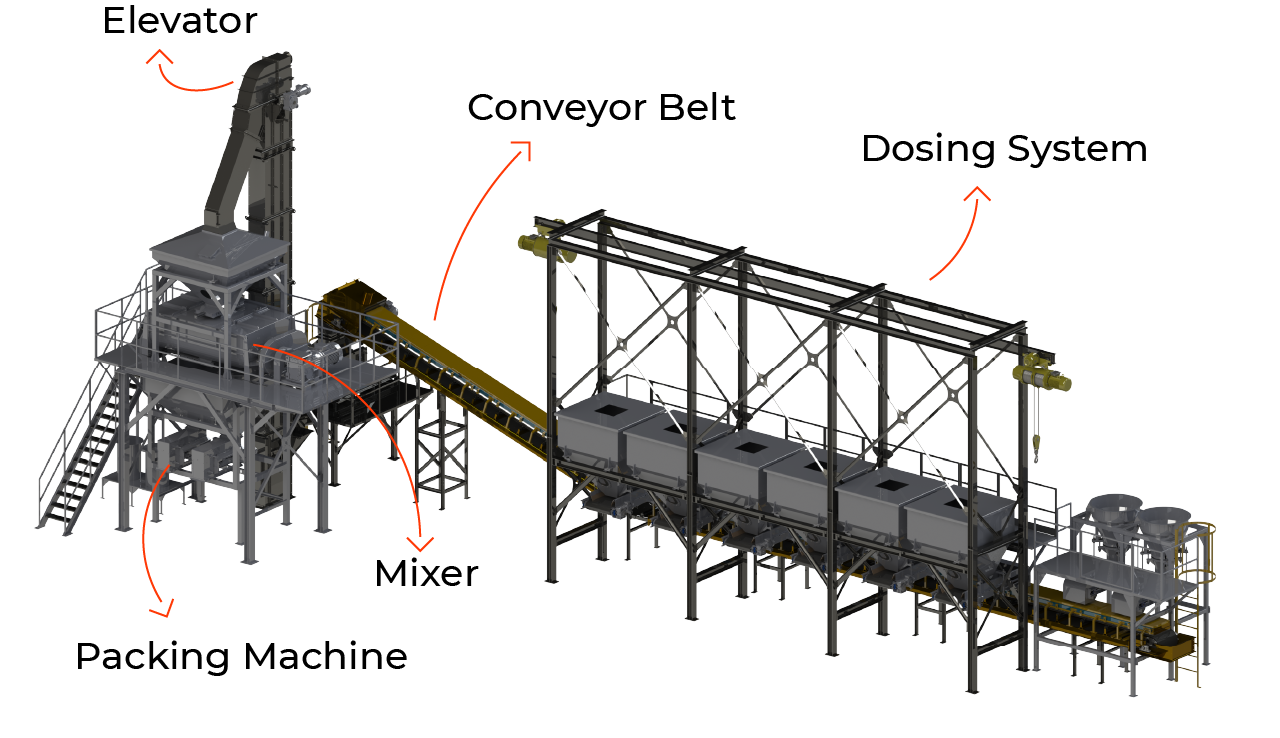

Dosing System

-

Dosing System

Precisely meters every solid or powder ingredient so the formulation keeps its exact recipe. Typical devices are loss-in-weight feeders or belt scales connected to a local PLC that alarms if any stream drifts outside tolerance. -

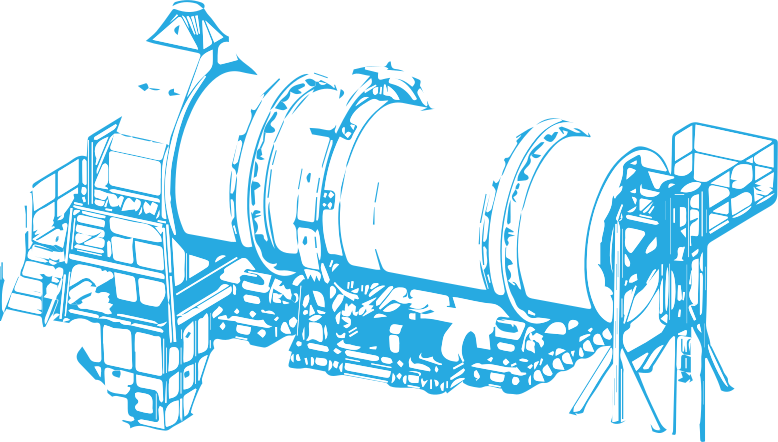

Granulation

Nuclei pick up fines with the help of binder until the mixture shape into strong granules of different sizes. Rotating drum or pan could be used for such purpose. -

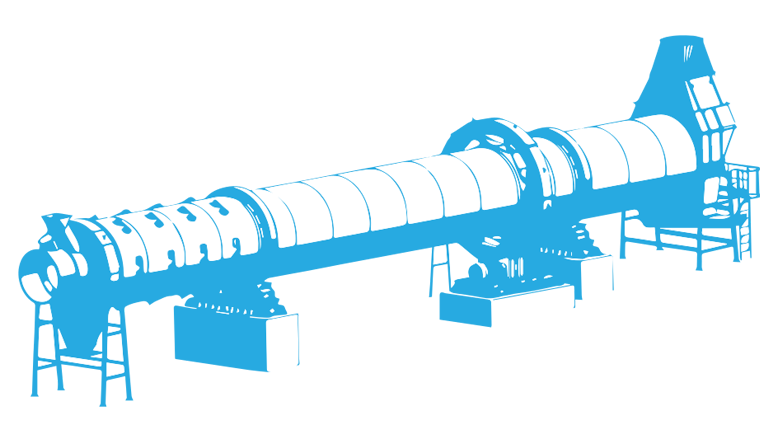

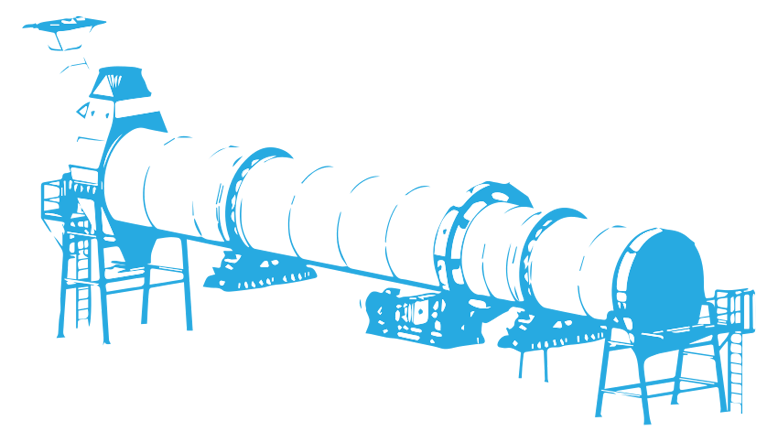

Drying

Hot air passes through a rotary dryer to evaporate free moisture from the fresh granules, raising their crush strength and preparing them for classification. -

Screening & Sifting

Vibrating or rotary screens classify the dried product into on-size granules, fines, and oversize. Fines go back to the granulator and oversize is routed to the crusher. -

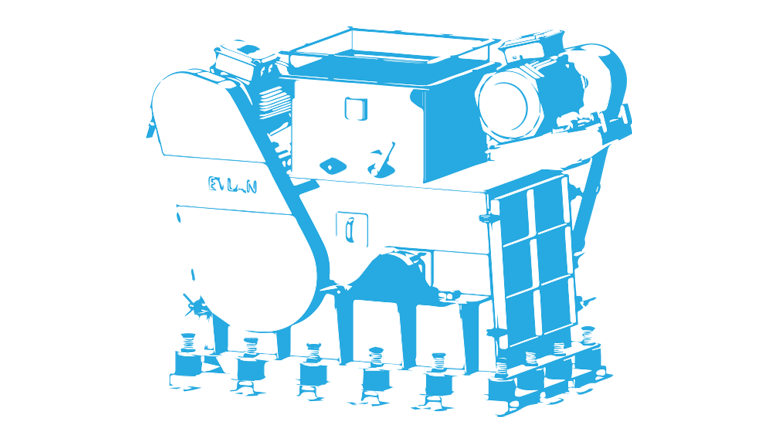

Crushing

A chain or hammer mill reduces the oversized granules from the screener into smaller particles so they can recycle as seed material in the granulation loop. -

Cooling

A counter-current rotary cooler lowers the product temperature to near ambient, preventing condensation and caking during storage or bagging.

Turnkey NPK Production Plant & Fertilizer Production Plant Solutions, Built for 24/7 Reliability

Our Processes

Bulk Blending & Soluble NPK Production Process

Bulk Blending & Soluble NPK Production Process

Our bulk blending facility for fertilizer process are designed to handle various raw materials and precise blending processes, guaranteeing consistent, high-quality output..

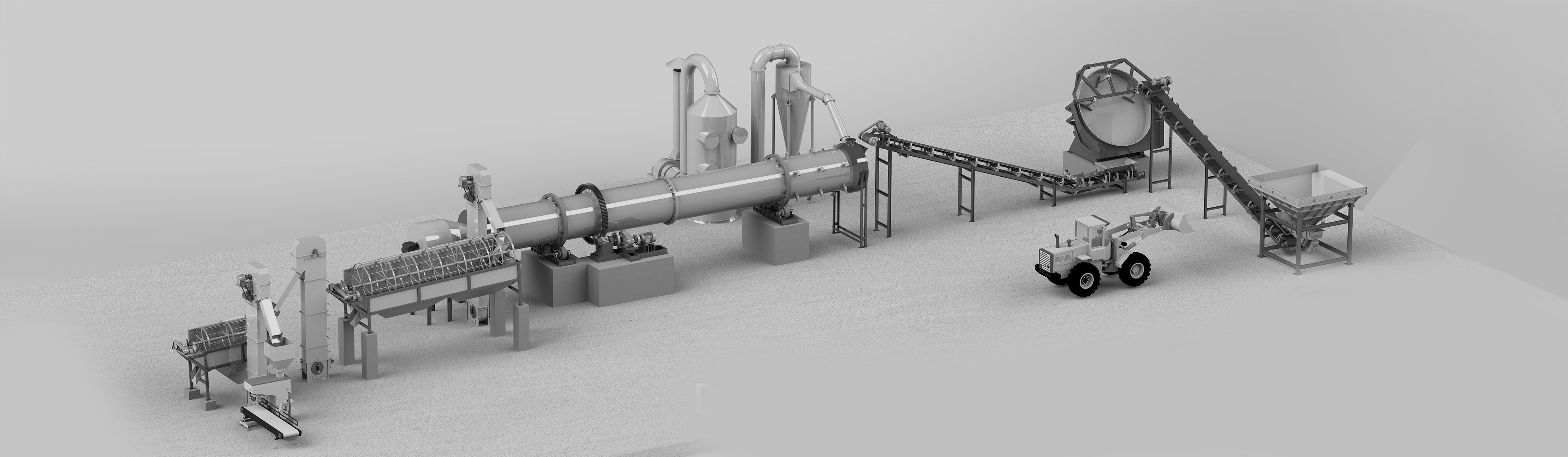

Granular Fertilizer Production Process

Granular Fertilizer Production Process

Maximize efficiency and guarantee superior product quality across NPK Production Lines— from precision raw-material dosing to final bagging and shipment.

Liquid Fertilizer Blending Process

Liquid Fertilizer Blending Process

Explore our granulation equipment designed to meet your industrial needs..

Dry Granulation Process (with roller press)

Dry Granulation Process (with roller press)

Explore our granulation equipment designed to meet your industrial needs.

Seasoned Specialists

With more than 30 turnkey projects on the board, our multidisciplinary crew of process engineers, mechanical designers, and automation experts speaks both the language of the shop floor and the C-suite.

Industry 4.0 DNA

Digital twins, closed-loop AI dosing, and cyber-secure PLC/SCADA architecture come standard—maximising throughput while squeezing energy use and emissions.

Strong Partnership

24 / 7 remote monitoring, rapid-response field teams, and data-driven maintenance programmes keep your OEE above 95 % year-round.

Sustainability Focus

We design processes that minimise waste, recover energy, and extend asset lifecycles—helping you meet environmental targets without compromising productivity.

Bolu NPK Production Plant 30 tons/hour

Samsun NPK Production Plant 30 tons/hour

Iskenderun 80 tons/hour twin NPK Production Plant

Antalya Micro Granular Fertilizer Production Plant 10 tons/hour

Mersin 15 tons/hour Bulk Blending Facility

Antalya Bulk Blending Facility 15 tons/hour

Build smarter plants, together.

From first feasibility study to first ton out, we deliver digital-ready fertilizer and chemical-process lines—safer, leaner, and greener.

We Design. We Build. You Grow.

We build facilities all over the world

Ceylan Liman Hizmetleri Makine İmalat San.ve Tic.Ltd.Şti

|

Çilek Mah. 63142 Sokak No:23 / A (Tırmıl Sanayi Sitesi Karşısı ) Akdeniz/Mersin |

|

E-Mail

|

|

Phone

|

|

Phone

|

|